RB

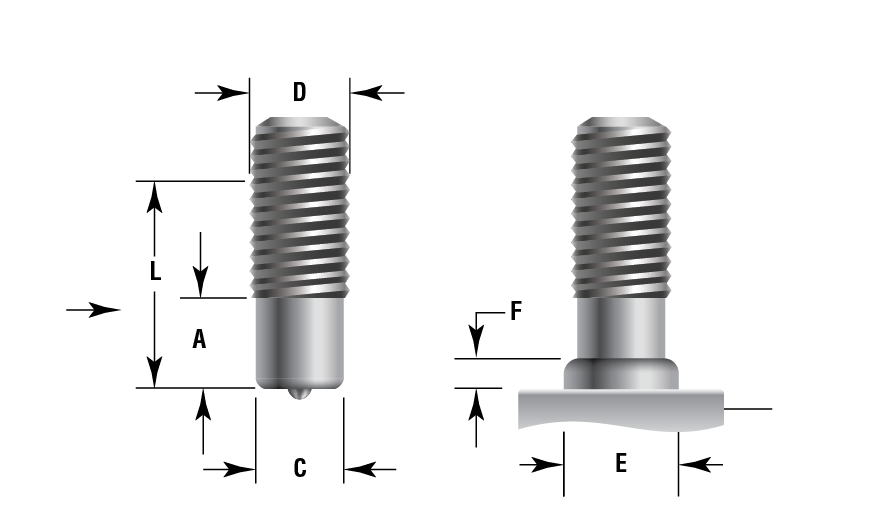

Reduced Base Stud

COX INDUSTRIES RB STUDS are designed for fastening applications where smaller clearance holes are required. They are available in diameters 1/4″ through 1″.

Alternate reduced base dimensions can be manufactured to allow a closer run-down of nut to the weld flash.

All orders for studs include required ferrules.

MATERIALS

- Low carbon steel ASTM A29/A108 Grades 1010-1020. Weldable stainless steels are available (except Type 303) with Type 302 being the most common.

LENGTH

- Studs can be produced in any length above the standard minimum (L). Length is listed before weld. Stud diameters 1/2" and below will be approximately 1/8" shorter after welding, 5/8” through 7/8" will be approximately 3/16" shorter after welding and 1" studs will be approximately 1/4" shorter after welding.

THREAD

- Standard thread is UNC-2A for imperial threads and 6g for metric threads.

PLATING

- Plating is used to increase a stud's corrosion resistance. Unless specified at time of order, all Cox studs will be supplied plain. Plating options include copper, nickel, zinc and zinc dichromat.

ANNEALING

- Upon request, stud ductility can be increased by annealing to 75 Rockwell B for low carbon steel and 90 Rockwell B for stainless steel.

FERRULES

- All orders for studs include required ferrules for welding. Please specify when ordering what type of ferrule is required for your application.

FLUX

- COX INDUSTRIES studs 1/4” and over are solid fluxed.

STUD SPECIFICATIONS

| D | Min L. | C | A | FILLET DIMENSION | |

|---|---|---|---|---|---|

| E | F | ||||

| 1/4 – 20 | 3/4 | 0.187 | 3/8 | 9/32 | 3/32 |

| 5/16 – 18 | 3/4 | 0.250 | 3/8 | 23/64 | 7/64 |

| 3/8 – 16 | 3/4 | 0.312 | 3/8 | 7/16 | 7/64 |

| 1/2-13 | 7/8 | 0.375 | 1/2 | 1/2 | 1/8 |

| 5/8-11 | 1 1/4 | 0.500 | 5/8 | 1 1/16 | 5/32 |

| 3/4-10 | 1 1/2 | 0.625 | 51/64 | 7/8 | 3/16 |

| 7/8-9 | 1 1/2 | 0.750 | 55/64 | 1-1/16 | 1/4 |

| 1-8 | 1 3/4 | 0.875 | 59/64 | 1-1/8 | 5/16 |

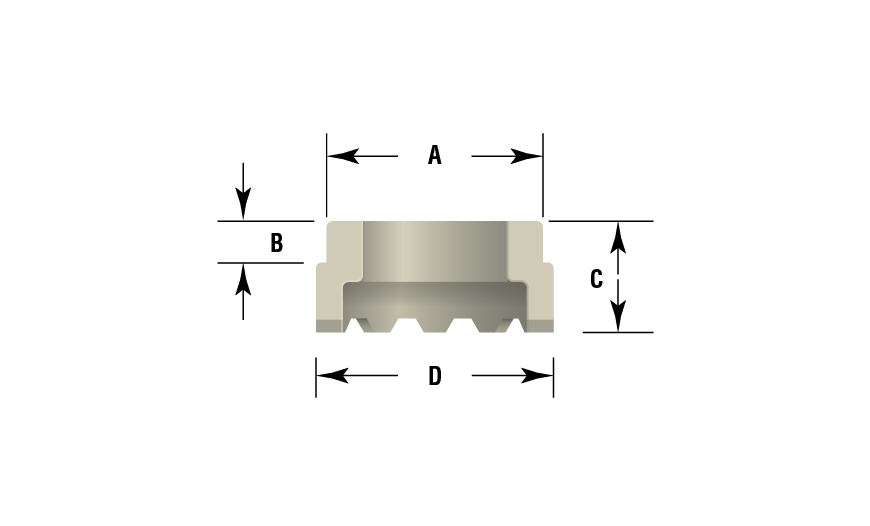

FERRULE SPECIFICATIONS

| FERRULE DIMENSIONS | ||||

|---|---|---|---|---|

| A | D | B | C | |

| 31FER | 0.305 | 0.390 | 0.240 | 0.390 |

| 14FER | 0.380 | 0.455 | 0.250 | 0.400 |

| 51FER | 0.445 | 0.578 | 0.240 | 0.390 |

| 38FER | 0.505 | 0.640 | 0.240 | 0.390 |

| 12FER | 0.650 | 0.795 | 0.265 | 0.445 |

| 58FER | 0.785 | 1.030 | 0.340 | 0.525 |

| 34FER | 1.030 | 1.235 | 0.465 | 0.656 |

| 78FER | 1.210 | 1.430 | 0.520 | 0.715 |

Mechanical Properties

| Type A | |

|---|---|

| Tensile Strength | 61,000 psi min. |

| Yield Strength | 49,000 psi min. |

| Elongation (% in 2″) | 17% min. |

| Elongation (% in 5x dia) | 14% min. |

| Reduction of Area | 50% min |

Type A studs shall be general purpose of any type and size used for purposes other than shear transfer in composite beam design and construction.