PS

Punching Shear Resistor

COX INDUSTRIES PSR STUDS are designed for welding to flat strip steel to reduce punching shear stress. When ordering specify overall height of rails and diameter of stud. All orders for studs include required ferrules.

MATERIAL

- Low carbon steel, ASTM A29/A108, 1010-1020

LENGTH

- Length is before weld. Stud diameters 1/2" and below will be approximately 1/8" shorter after welding and studs 5/8" and larger will be approximately 3/16" shorter after welding. Maximum length available for cold headed product is 10-7/8". Prices on hot formed studs over 10-3/16" available upon request.

FLUX

- COX INDUSTRIES PSR Studs are solid fluxed.

STUD SPECIFICATIONS

| D | A | H | HA/SA | Base Rail | |

|---|---|---|---|---|---|

| Rt | Rw | ||||

| 3/8 | 0.210 | 1.190 | 10.100 | 3/16 | 1 |

| 1/2 | 0.280 | 1.580 | 10.000 | 1/4 | 1–1/4 |

| 5/8 | 0.350 | 1.980 | 10.000 | 5/16 | 1–3/4 |

| 3/4 | 0.420 | 2.370 | 10.000 | 3/8 | 2 |

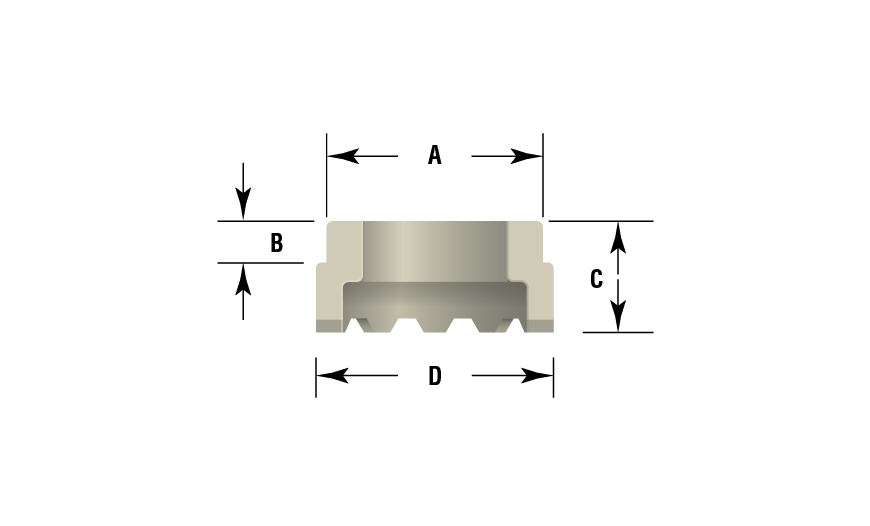

FERRULE SPECIFICATIONS

| FERRULE DIMENSIONS | ||||

|---|---|---|---|---|

| NO. | A | D | B | C |

| 38FER | .505″ | .640″ | .150″ | .390″ |

| 12FER | .650″ | .795″ | .180″ | .445″ |

| 58FER | .785″ | 1.030″ | .185″ | .525″ |

| 34FER | 1.030″ | 1.235″ | .191″ | .656″ |

Mechanical Properties

| Type B | |

|---|---|

| Tensile Strength | 65,000 psi min. |

| Yield Strength | 51,000 psi min. |

| Elongation (% in 2″) | 20% min. |

| Elongation (% in 5x dia) | 15% min. |

| Reduction of Area | 50% min |

Type B studs shall be studs that are headed, bent, or of other configuration in 3/8” [10 mm], 1/2” [12 mm], 5/8” [16 mm], 3/4″ [20 mm], 7/8” [22 mm], and 1” [25 mm] diameter that are used as an essential component in composite beam design and concrete anchorage design.