TP

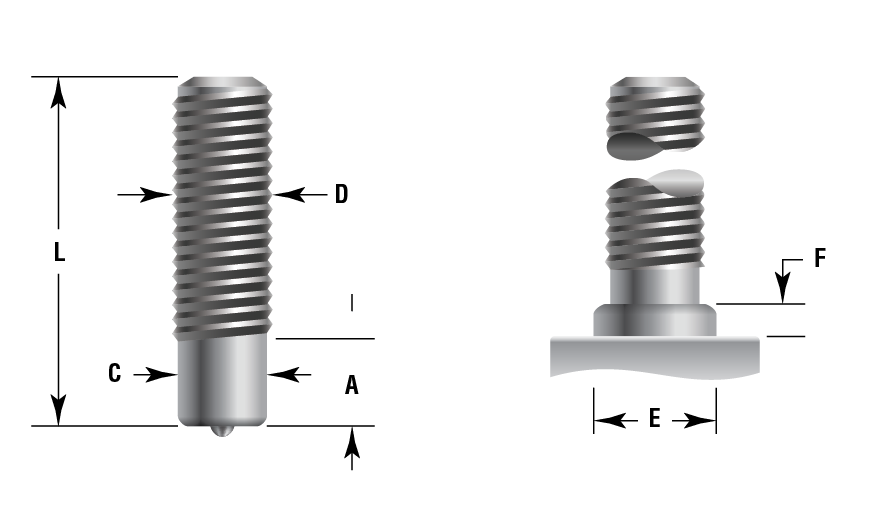

Partial Thread Stud

COX INDUSTRIES TP STUDS are designed for fastening applications where full fastener strength is required. The unthreaded area helps reduce stud hang up during the weld process. Diameters are available in 1/4″ through 1″.

All orders for studs include required ferrules.

MATERIALS

- Low carbon steel ASTM A29/A108 Grades 1010-1020. Weldable stainless steels are available (except Type 303) with Type 302 being the most common.

LENGTH

- Studs can be produced in any length above the standard minimum (L). Length is listed before weld. Stud diameters 1/2" and below will be approximately 1/8" shorter after welding, 5/8” through 7/8" will be approximately 3/16" shorter after welding and 1" studs will be approximately 1/4" shorter after welding.

THREAD

- Standard thread is UNC-2A for imperial threads and 6g for metric threads.

PLATING

- Plating is used to increase a stud's corrosion resistance. Unless specified at time of order, all Cox studs will be supplied plain. Plating options include copper, nickel, zinc and zinc dichromat.

ANNEALING

- Upon request, stud ductility can be increased by annealing to 75 Rockwell B for low carbon steel and 90 Rockwell B for stainless steel.

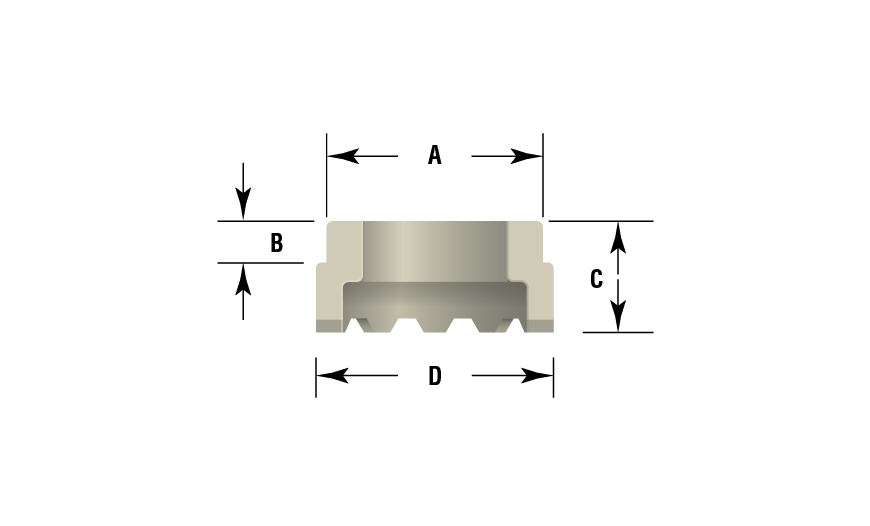

FERRULES

- All orders for studs include required ferrules for welding. Please specify when ordering what type of ferrule is required for your application.

FLUX

- COX INDUSTRIES studs 1/4” and over are solid fluxed.

STUD SPECIFICATIONS

| D | Min L. | C | A | FILLET DIMENSION | |

|---|---|---|---|---|---|

| E | F | ||||

| 1/4-20 | 3/4 | 0.215 | 3/8 | 5/16 | 3/32 |

| 5/16-18 | 3/4 | 0.275 | 3/8 | 13/32 | 7/64 |

| 3/8-16 | 3/4 | 0.330 | 3/8 | 7/16 | 7/64 |

| 7/16-14 | 7/8 | 0.387 | 7/16 | 1/2 | 1/8 |

| 1/2-13 | 7/8 | 0.448 | 1/2 | 19/32 | 5/32 |

| 5/8-11 | 1 | 0.562 | 5/8 | 3/4 | 3/16 |

| 3/4-10 | 1-3/16 | 0.680 | 51/64 | 59/64 | 1/4 |

| 7/8-9 | 1-3/8 | 0.798 | 55/64 | 1 | 5/16 |

| 1-8 | 1-1/2 | 0.915 | 59/64 | 1-1/8 | 5/16 |

FERRULE SPECIFICATIONS

| FERRULE DIMENSIONS | ||||

|---|---|---|---|---|

| NO. | A | D | B | C |

| 14PFER | 0.380 | 0.455 | 0.125 | 0.250 |

| 51PFER | 0.445 | 0.535 | 0.125 | 0.250 |

| 38PFER | 0.505 | 0.595 | 0.139 | 0.264 |

| 71PFER | 0.585 | 0.675 | 0.173 | 0.329 |

| 12PFER | 0.650 | 0.740 | 0.206 | 0.362 |

| 58PFER | 0.785 | 0.905 | 0.277 | 0.433 |

| 34PFER | 1.030 | 1.150 | 0.339 | 0.526 |

| 78PFER | 1.210 | 1.330 | 0.406 | 0.593 |

| 1PFER | 1.410 | 1.525 | 0.470 | 0.660 |

Mechanical Properties

| Type A | |

|---|---|

| Tensile Strength | 61,000 psi min. |

| Yield Strength | 49,000 psi min. |

| Elongation (% in 2″) | 17% min. |

| Elongation (% in 5x dia) | 14% min. |

| Reduction of Area | 50% min |

Type A studs shall be general purpose of any type and size used for purposes other than shear transfer in composite beam design and construction.